Aerospace case for electronics

Aerospace Clip

Aerospace Plastic Injection Molding

HiTech Plastics and Molds has been an injection molding plastics products and subcomponents supplier to the Aerospace Industry for 30+ years. Aerospace plastic injection molded components and parts must be built with the greatest precision. Aerospace plastic parts and components can only be made according to perfect specifications and accurate measurements.

In order to maintain our Aerospace plastic parts and components customer base, one which requires conforming to strict regulations and standards, we have injection molding specialists ready to help you with Scientific Molding and Mold Flow Analysis. All of our aerospace injection molded parts and components maintain strict quality management procedures.

Injection Molded Aerospace Components & Parts

Plastic products and components in the Aerospace Industry that we are proud to supply include:

- Radomes of all shapes and sizes

- Plastic aerospace parts and components used in unmanned aircraft

- Battery housings

- Circuit boxes

- Spacers

- Knobs

- Spinners

- Connectors

- Pitot tubes

- Enclosures

Aerospace Injection Molding Plastic Materials

HiTech is a leader in injection molding both engineering materials and commodity based plastic resins. Molded products range from Homo & Copolymer PP, HDPE, HIPS, ABS to exotic materials, including Xenoy, Ultem, PEEK, and TPU/TPV materials.

We have formed relationships with several color houses with whom we work to make sure our customer can have a molded product in the exact color they choose.

Simple & Complex Injection Molded Aerospace Components

Aerospace Overmolding Services

Overmolding is the molding process in which two or more materials are combined to produce a single part. Typically the aerospace part seamlessly binds a rigid plastic with a softer rubber like material. The result is both valuable for creating a non-slip surface and for cosmetic value. Over molding is used most often in aerospace, medical, and consumer products.

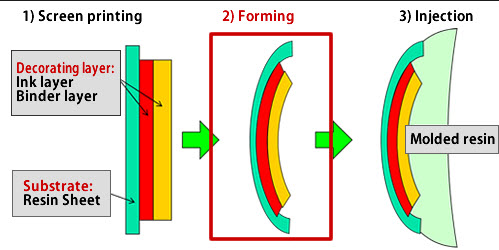

Aerospace In-Mold Decorating and In-Mold Labeling Services

When required we are able to incorporate In-Mold decorating for Aerospace components and parts.

Aerospace Insert Molding Services

HiTech also has expertise in insert molding when desired in making simple to complex aerospace parts. Insert molding combines metal and plastics, or other combinations of aerospace material and components during the injection molding process. The process generally uses engineering grade plastic material for improved quality, strength, and wear resistance with the metal inserts used for reinforcing mechanical properties of the part and for conductivity purposes.

Aerospace Sonic Welding Services

Many of our aerospace parts require sonic welding. We are experienced in this process which securely bonds two similar materials by movement of sound waves, softening the materials and facilitating strong adhesion.

Aerospace Components & Product Development

Our team works with aerospace companies in different areas of product development from initial prototyping to mass production. Our engineers work closely with the aerospace engineers and designers to ensure the parts meet performance criteria. All aerospace parts are made according to challenging specifications and accuracy.

Attention to detail while designing aerospace molds and manufacturing aerospace components and parts assures the customer that the parts will endure demanding conditions required in aerospace applications. HiTech has the unique capability of providing customers with design support for new product development leveraging leading thinkers and product development sources around the country with whom we have developed professional partnerships.

Working With HiTech Plastics and Molds

Our molds for aerospace injection molding are built in our onsite tool shop where we have experience in building molds for a combined total of 30+ years. Our tool makers can provide customers with design support, working with Aeronautic Engineers to determine the best design for each mold, therefore, assuring conformance, precision, and consistent quality for these specialized parts.

For Your Aerospace Components & Parts Trust HiTech Plastics

HiTech Plastics and Molds is a trusted aerospace injection molding company with decades of expertise. We deliver high-quality aerospace components and parts that will and exceed your expectations.

Please contact our team at 818-477-2777 for general questions or request a quote to expedite your response.