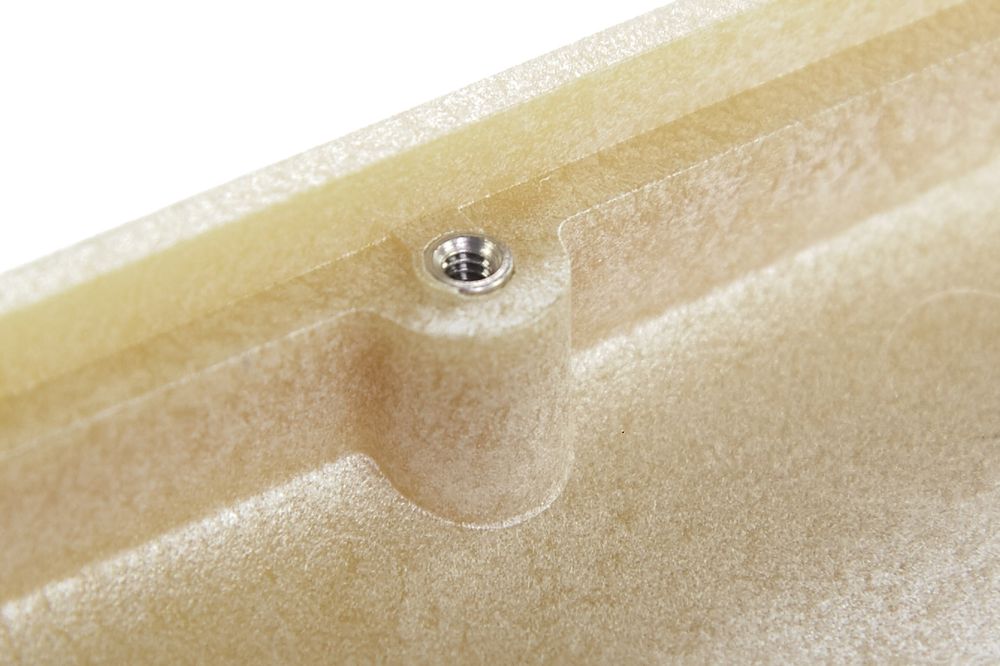

Insert Molding

Custom Injection Molding

The HiTech Plastics & Molds leadership team has over 100 years combined experience in manufacturing injection molded thermoplastic parts and assemblies. Our exacting standards and professional workmanship consistently produce top-quality, close tolerance custom injection molded parts for everything from consumer goods to irrigation components. With injection press sizes ranging from 95 to 500 tons, we can handle a wide range of part geometries.

In addition to thermoplastic injection molding, we have considerable experience in Insert Molding, Over Molding, single cavity molding, or high cavitation molding. Secondary capabilities include assembly included sonic welding, Tampo printing, machining & final packaging.

What is the Plastic Injection Molding Process?

Injection molding is a manufacturing solution used to create custom plastic parts with quick turnaround times. Before mass producing your custom plastic parts, you must first have a custom injection mold built for your manufacturing line. Molten thermoplastic is then injected into the mold to form your plastic part. Inside the mold, the plastic cools and hardens into your custom component. The plastic part is ejected, inspected, and delivered to you with further processing or including sub assemblies if needed.

In-House Design, Engineering, and Plastic Injection Molding

HiTech takes your product from design conception to being production-ready. Our in-house engineering staff utilizes the latest CAD/CAM software to design your mold and product with precision. Trained in Scientific Molding by the top experts in the USA, they carefully review your 3-D drawings before mold building to identify and correct anything that could affect your product’s design.

All products are “Made in the USA” and include green recycled materials when the application allows or the customer specifies.

Plastic Injection Molding Material Options

HiTech is a leader in the injection molding of engineering materials. The plastic materials typically used in production include commodity grade resins (HIPS, PP & HDPE) and exotic engineered plastics like Xenoy & the Ultem family of resins. When specified, we can add Pantone colors or UV screening to your thermoplastic resin.

We work with the following types of thermoplastic, all sourced from suppliers that follow strict standards for material certification and traceability:

- Engineering grade materials include high-performance and exotic thermoplastic resins exhibiting exceptional mechanical properties. These molding resins are best for aerospace, medical, and other applications requiring high strength, thermal or chemical resistance, or other special properties.

- Commodity grade materials are produced in high volume and used to make most standard plastic parts and products, like film packaging and household products. These polymers have less outstanding mechanical properties than engineering-grade materials and are not recommended for engineering applications.

Various details go into selecting a thermoplastic resin for custom injection molding, including moldability, tolerance, and other material properties. The final selection of plastic materials to use in each particular application is always the customer’s decision; however, we can assist you with material selection and design for manufacturability.

Injection Molding Services

We take your product from design through production. Our in-house engineering staff utilizes the latest CAD/CAM software to design your injection molded plastic parts with precision. Trained in Scientific Molding by the top experts in the USA, our team carefully reviews your 3D drawings to identify and correct anything that could affect your final product.

What Can I Make with Plastic Injection Molding?

Injection molding can manufacture virtually any large-volume order of small or mid-sized plastic parts. From children’s toys to spacecrafts, medical devices to irrigation components, injection molded plastic parts are used in most of our day-to-day lives. In the past, HiTech has created high-quality injection molding solutions such as:

Plastic Injection Molding for Any Industry

From design to manufacturing, HiTech Plastics & Molds has every stage of your custom thermoplastic injection molded part covered. We provide plastic injection molding services for many industries and applications, including:

- Award-winning package/closure caps

- Radomes/aerospace

- Drone aircraft parts

- Award-winning construction parts

- Drip irrigation & drainage products

- Medical products

- Apple iPhone cases

- And many others.

What Are the Different Types of Injection Molding?

While all injection molding processes follow similar steps, there are a variety of injection molding services available. HiTech’s expert engineering team will discuss your application’s requirements and goals to determine which plastic molding system best suits your desired outcome. Thermoplastic service choices include, but are not limited to:

- 2-shot injection molding

- Insert molding

- Overmolding

- Single cavity molding

- High cavitation molding

No matter the variety of plastic molding you require, HiTech Plastics has the capabilities to produce a custom injection mold and produce plastic parts that match your exact specifications.

What Plastics Are Used in Injection Molding?

Various details go into selecting a thermoplastic resin for custom injection molding, including moldability, tolerance, and other material properties. The final selection of plastic materials to use in each application is always the customer’s decision. However, we can assist you with material selection and design for manufacturability.

HiTech is a leader in the injection molding of any resin to manufacture custom plastic parts. We work with two main types of resin: engineering-grade materials and commodity-grade materials. All our thermoplastics are sourced from suppliers that follow strict standards for material certification and traceability.

Engineering Grade Materials

Engineering-grade materials include high-performance and exotic thermoplastic resins exhibiting exceptional mechanical properties. These injection molding plastics are best for aerospace, medical, and other applications requiring high strength, thermal or chemical resistance, or other special properties.

Commodity Grade Materials

Commodity-grade materials are produced in high volume and used to make most standard injection-molded plastic parts and products, like film packaging or household products. These polymers have less outstanding mechanical properties than engineering-grade materials and are not recommended for engineering applications.

Strong Commitment to Quality and Customer Service

Our philosophy is that quality and customer satisfaction are of utmost importance. We have achieved customer confidence in our abilities by consistently satisfying customer needs and producing high-quality parts. One measure of our quality and performance is the many customers who have worked with us for 20 years or more.

When you choose HiTech for your custom plastic injection molding project, you can count on:

- Extensive product and materials knowledge

- Competitive pricing

- Problem-solving to achieve the best design outcome

- On-time completion

Let’s Talk About Your Custom Injection Molding Project!

HiTech Plastics & Molds provides industry-leading injection molding services to southern California and beyond. Our specialists have the thermoplastic injection molding expertise to handle any project. Contact us to discuss your requirements or request a quote to get started on your injection molded application today!

Contact us to discuss your requirements or request a quote to get started on your injection molded application today!