Insert Molding

Assembly and Secondary Operations in Injection Molding

At HiTech Plastics and Molds, we go beyond the primary injection molding process to provide comprehensive solutions to our clients. In addition to manufacturing high-quality plastic components, we offer a range of assembly and secondary operations to ensure your project's success.

Assembly

Assembly refers to the process of combining multiple injection-molded components and other elements to create a finished product. Our experienced assembly team carefully integrates various parts, ensuring proper alignment, fit, and functionality. We take pride in our attention to detail and strive for flawless assembly to meet your specific requirements.

Above: Assembly made up of 23 sub-parts (completed item on right).

Secondary Operations

In addition to assembly, we offer a variety of secondary operations to enhance the functionality, appearance, and overall quality of your injection-molded parts. These operations include:

- CNC Milling: CNC milling is a precision machining process that involves removing material from a plastic component using computer-controlled milling machines. This operation allows us to achieve tight tolerances, complex geometries, and precise finishes. Our state-of-the-art CNC milling equipment, combined with skilled technicians, ensures the highest level of accuracy and consistency in every part we produce.

- Ultrasonic Bonding: Ultrasonic bonding is a popular and cost-effective technique that uses friction and heat to bond plastics. This method of plastic part assembly is applied most often when the plastic materials used are compatible and when your result requires a permanent seal.

- Mechanical Fastening: Mechanical fastening uses screws, rivets, and press fits for plastic component assembly and sub-assembly. This method is used when the product needs to be disassembled during its lifetime. Mechanical fastening assemblies are generally used in low-volume applications.

- Solvent & Adhesive Bonding: Adhesives are used in applications where the materials are not compatible, and a permanent plastic solution is required. There are many types of adhesives, so HiTech will work closely with the supplier to determine the adhesive that is best suited to assemble your plastic parts.

- Finishing and Surface Treatment: We understand the importance of aesthetics and offer a range of finishing and surface treatment options. These include smoothing rough edges, removing flash or imperfections, and applying various coatings, such as painting, plating, or custom finishes. Our goal is to deliver injection-molded parts that not only meet your functional requirements but also have a professional and visually appealing appearance.

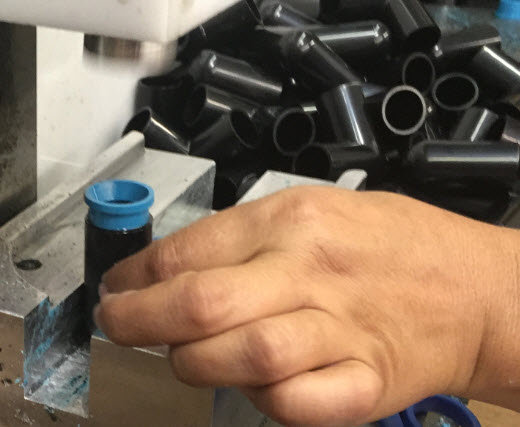

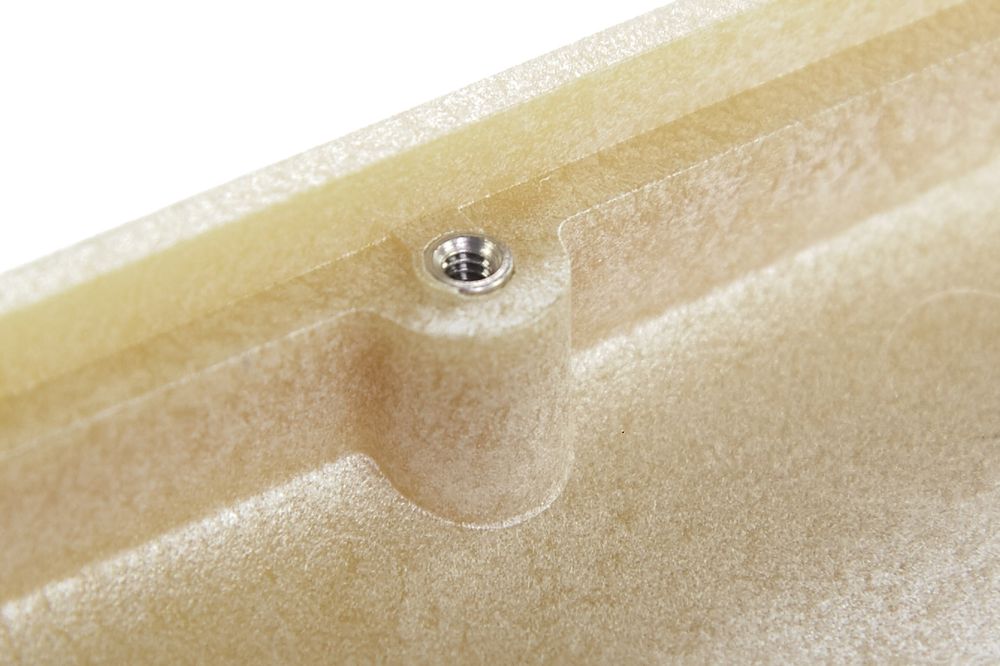

- Inserting and Overmolding: Insert molding involves the integration of pre-manufactured components, such as metal inserts or electronic parts, into the injection-molded part during the molding process. This technique ensures a strong bond between the insert and the plastic, resulting in increased strength and functionality. Overmolding, on the other hand, involves molding one material over another, creating multi-material or soft-touch components. These techniques expand the design possibilities and provide added value to your products.

- Assembly and Sub-Assembly: Our assembly capabilities extend beyond simple component integration. We can handle complex assemblies and sub-assemblies, combining various injection-molded parts, fasteners, electronics, and other components. Our team carefully follows assembly instructions and quality control processes to ensure each assembly meets your specifications.

Quality Assurance

Throughout the assembly and secondary operations processes, we maintain strict quality control measures. Our dedicated quality assurance team performs inspections and tests to verify the dimensional accuracy, functionality, and overall quality of the finished products. We adhere to industry standards and continuously invest in advanced equipment and training to deliver exceptional results.

At HiTech Plastics and Molds, we take pride in offering comprehensive solutions that go beyond injection molding. Our expertise in assembly and secondary operations, including CNC milling, enables us to meet your specific project requirements and deliver high-quality, fully functional parts. Partner with us to experience the difference of our integrated manufacturing capabilities.

Contact Us

Request a quote or contact us today to discuss your assembly and secondary operation needs for injection molding.