Insert Molding Services at HiTech Plastics and Molds

At HiTech Plastics and Molds, we specialize in providing high-quality insert molding services to meet the unique needs of our clients. Insert molding is a versatile plastic injection molding process that allows for the integration of metal or other pre-formed components directly into the molded plastic parts. It offers numerous advantages, including enhanced product functionality, improved assembly efficiency, and cost savings.

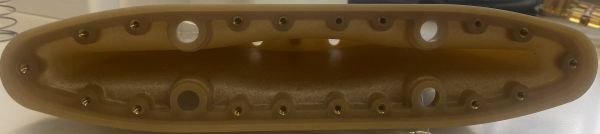

Above: Ultem-based part with 18 brass inserts manufactured by HiTech.

How Does Insert Molding Work?

Insert molding involves placing a pre-formed insert, such as a metal component or another plastic part, into the mold cavity before the injection molding process begins. The molten plastic material is then injected into the mold, surrounding and encapsulating the insert. Through precise control of temperature, pressure, and timing, the plastic material bonds with the insert, creating a strong and seamless integration.

Benefits of Insert Molding:

-

Enhanced Product Functionality: Insert molding allows for the integration of multiple components or features into a single molded part, eliminating the need for additional assembly steps. This leads to improved product functionality, reduced part complexity, and increased design possibilities.

-

Improved Assembly Efficiency: By combining multiple components into a single molded part, insert molding simplifies the assembly process, reducing assembly time and labor costs. It also minimizes the risk of component misalignment or detachment during assembly.

-

Cost Savings: Insert molding offers cost-saving opportunities by eliminating the need for secondary operations, such as welding, fastening, or adhesive bonding. Additionally, it enables the use of less expensive materials for certain components, without sacrificing quality or performance.

-

Enhanced Durability and Strength: The bonding between the insert and the plastic material in insert molded parts enhances their structural integrity, providing increased durability and strength. This is particularly advantageous for applications that require robust and reliable components.

-

Design Flexibility: Insert molding provides designers with greater freedom in product design. It allows for the incorporation of intricate geometries, unique shapes, and diverse materials into a single molded part, enabling the creation of innovative and customized solutions.

Applications of Insert Molding:

Insert molding finds wide applications across various industries, including automotive, electronics, medical devices, consumer goods, and more. Some common examples include:

- Electrical connectors with metal contacts embedded in plastic housings

- Overmolded handles and grips with embedded reinforcement inserts

- Medical devices with integrated metal or plastic components

- Automotive parts with encapsulated electronics or threaded inserts

Trust HiTech Plastics and Molds for Your Insert Molding Needs

At HiTech Plastics and Molds, we have extensive expertise to deliver exceptional insert molding solutions. Our team of experienced engineers and technicians work closely with clients to understand their requirements and provide customized solutions tailored to their specific needs. We ensure strict quality control throughout the entire manufacturing process to deliver superior products that meet or exceed industry standards.

Contact us today to discuss your insert molding project and experience the quality and expertise that HiTech Plastics and Molds has to offer.

Contact Us

Request a quote or contact us today to discuss your custom insert molding requirements.